Nominal diameter: DN100 ~ 1200mm, NPS4 "~ 48"

Nominal pressure: 150Lb pounds / PN25

Suitable temperature: Carbon steel: -29 ℃ ~ 425 ℃ Stainless steel: -40 ℃ ~ 650 ℃

Applicable medium: water, steam, hot water, oil

drive Type: worm gear, electric, pneumatic, hydraulic

welding standards: GB12224, ANSI B16,25, DIN2559

First, SD363H welding bi-directional pressure butterfly Product Overview

Our company can introduce advanced foreign technology, based on sophisticated J-shaped elastic ring and three eccentric multi-layer metal seal structure, is widely used in metallurgy, electric power, petrochemicals, as well as water supply and drainage and municipal construction and other industrial pipelines On, for regulating the flow and breaking fluid use. The valve adopts three eccentric structure, the valve seat and the disc sealing surface are made of different hardness and stainless steel, has good corrosion resistance, long service life, the valve Jun mail two-way sealing function, the product complies with national GB / T13927-92 valve pressure Test Standard.

Second, SD363H welding bidirectional butterfly valve product features

1, the use of three eccentric butterfly valve can be called the top process valve, the design of the valve for the high temperature, high pressure, fire-rated foam sealing ideal for sealing the ideal butterfly valve.

2, due to the use of welding structure, so that the valve and the pipeline plane to achieve a permanent zero leakage.

3, the valve can not be flanged, bringing great convenience and beautiful appearance to the pipe and insulation bandaging.

Third, SD363H welding two-way pressure butterfly valve main technical parameters

| Nominal diameter DN (mm) | DN100 ~ 1200mm, NPS4 "~ 48" |

| Nominal pressure PN (Mpa) | Strength test (1.5 × PN) Seal test (1.1 × PN) |

| proper temperature | Carbon steel: -29 ℃ ~ 425 ℃ Stainless steel: -40 ℃ ~ 650 ℃ |

| Suitable media | Water, steam, hot water, oil |

| Drive mode | Worm gear, electric, pneumatic, hydraulic |

| Pressure Level | ANSI 150Lb Pound / PN25 |

| Welding standards | GB12224, ANSI B16,25, DIN2559 |

SD363H welding two-way pressure butterfly valve main components and materials

| Part Name | material |

| Body | Carbon steel, stainless steel, chrome-aluminum steel |

| Butterfly plate | Carbon steel, alloy steel, stainless steel |

| Seat | 3 stainless steel, cobalt-based cemented carbide |

| Sleeve | stainless steel |

| Valve stem | Stainless steel, special materials |

| filler | Flexible graphite |

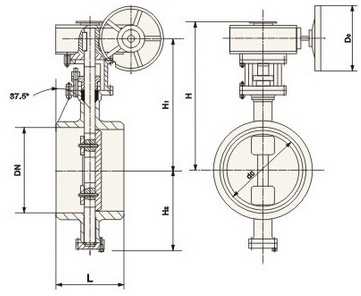

D363H / 663H / 963H / -10 / 16/25/40 / C, P, RSD363H Welding Bidirectional Butterfly Valve Connection Size

| Pass through | Main dimensions | Pass through | Main dimensions | ||||||

| in | DN (mm) | L | H1 | H | in | DN (mm) | L | H1 | H |

| 4 | 100 | 190 | 270 | 370 | 18 | 450 | 330 | 535 | 820 |

| 5 | 125 | 200 | 295 | 390 | 20 | 500 | 350 | 560 | 900 |

| 6 | 150 | 210 | 308 | 416 | 24 | 600 | 390 | 630 | 980 |

| 8 | 200 | 230 | 370 | 530 | 28 | 700 | 430 | 670 | 1100 |

| 10 | 250 | 250 | 450 | 580 | 32 | 800 | 470 | 800 | 1300 |

| 12 | 300 | 270 | 465 | 630 | 36 | 900 | 510 | 850 | 1370 |

| 14 | 350 | 290 | 475 | 595 | 40 | 1000 | 550 | 880 | 1480 |

| 16 | 400 | 310 | 505 | 755 | 48 | 1200 | 630 | 1000 | 1690 |

+86-021-55522202

+86-021-55522202